EQUIPMENT

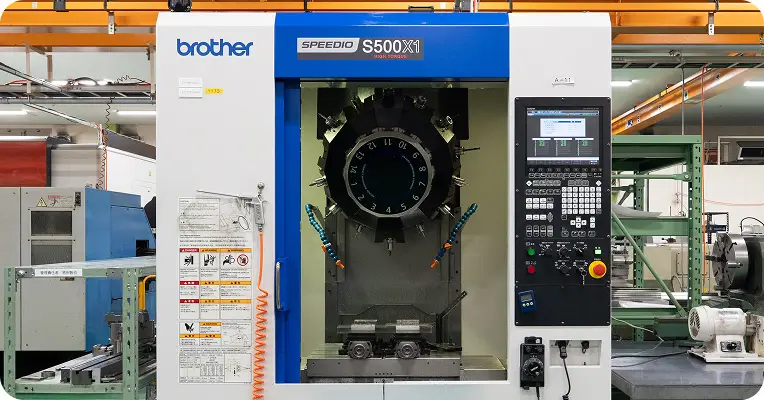

Machining Center

Equipped with a touch panel and 3D tool path to enable quick program creation

X:1950mm、Y:530mm、Z:510mm

Supports heavy cutting, the largest table size and stroke in its class allow for large jigs and workpieces to be mounted

X:1530mm、Y:700mm、Z:650mm

Joining processing allows lengths over 2000mm, specializing in processing aluminum materials

X:1950mm、Y:510mm、Z:510mm

Vertical Machining Center capable of machining long workpieces with high precision

X:1050mm、Y:530mm、Z:510mm

Equipped with a CNC-C00 control device, achieves both high productivity and space saving

X:500mm、Y:400mm、Z:300mm

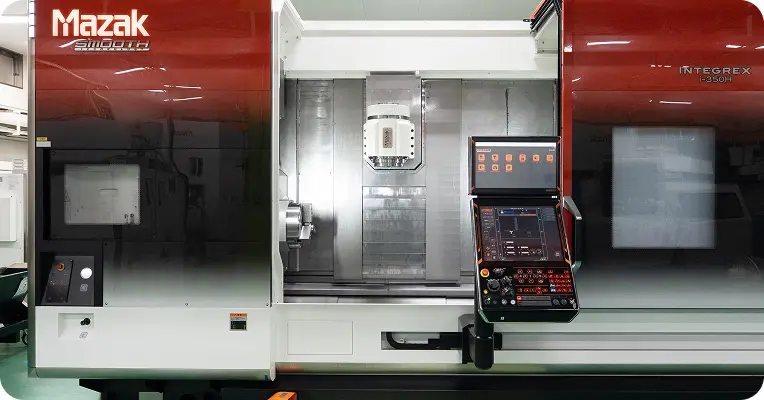

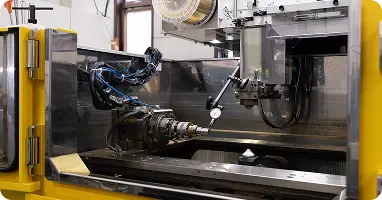

NC lathe

A multi-tasking machine that combines advanced multi-axis machining and AI technology to achieve high-precision machining of large workpieces

Φ350mm×1100L

Operation panel with touch panel enables good operability and quick program creation. The vertical type allows for the machining of heavy workpieces, and the auto tool change function allows for machining up to φ 450mm without tool interference

Φ450mm×462L

A high-speed, high-precision built-in motor spindle and milling function makes highly efficient combined machining of a variety of workpieces possible

Highly rigid structure and built-in motor spindle enable highly accurate and efficient lathe turning and milling.

Spindles

Φ350mm×650L

Processes small to up to φ 200mm workpieces. With a tailstock, the maximum processing length is 540mm

Φ212mm×541L

Band Saw (automatic)

Band saw machine equipped with NC program cutting function

Multiple products with different cutting lengths can be set from one material, with continuous automatic cutting

Cutting various materials

Φ10~420mm

Φ10mm×10mm~400mm×400mm

Gringer

A multi-purpose grinder capable of simultaneous surface, internal and external cylindrical grinding

Grinding depth up to 230mm

Inner diameter φ30 - 400

Outer diameter φ500 Length 325

Highly rigid column-type structure, can support long workpieces up to 2000mm

X:2000mm、Y:240mm、Z:300mm

Dedicated grinding machine for sharpening cutter blades

X:600mm、Y:120mm、Z:600mm

Dedicated grinding machine for sharpening cutter blades

X:600mm、Y:120mm、Z:600mm

Highly rigid column-type machine. Outstanding straightness with both the longitudinal axis and cross axis

X:1200mm、Y:240mm、Z:300mm

Precision Surface Grinder equipped with automatic dressing function, shift plunge function, large touch panel, etc.

X:600mm、Z:400mm

Column-type highly rigid machine

Precision Surface Grinder equipped with automatic dressing function and large touch panel

X:800mm、Y:450mm、Z:400mm

Precision Surface Grinder equipped with automatic dressing function, shift plunge function, large touch panel, etc.

X:600mm、Z:300mm

A rotary surface grinder with a unique gate-type structure whose original controller achieved 0.1µm infeed setting

Φ800

Internal Grinding Machine φ19 - φ160. Grinding stroke up to 100mm

Tapering from 0 to 15 degrees available, we have 2 machines

Φ15~Φ200 L=110

Metal spindle enables highly efficient and high-quality grinding of hard and tough materials.

Tapering up to 5 degrees available, we have 4 machines

Φ420mm×170mm

High-precision internal and external grinding available. Suitable for a variety of workpieces.

Spindles

Φ400mm×1000mm

Rotary blade sharpener

Φ50~20mm

Discharge Machine

A wire-cut electric discharge machine specializing in high-precision micromachining. One of its features is the use of an oil-based machining fluid, which narrows the discharge gap and is advantageous for fine machining. This also provides an excellent surface finish.

X:200 Y:200 Z:60

Wire diameter: φ0.05 - φ0.2

Thanks to the finishing SF3 power supply, which generates finer and higher frequency discharge pulses, as well as optimization of machining conditions and speed at corners and steps using discharge control iPulse3, operators can achieve workability at greater speeds and exceptional precision cutting as well as improved surface finishes. High-precision processing is possible regardless of the hardness of the material.

X:600 Y:400 Z:310

Wire diameter: φ0.1 - φ0.3

Makino’s unique control technology enables high-quality machined surfaces and high form accuracy. Compensates thermal displacement of the machine caused by temperature changes during processing, maintaining stable high precision even during long processing periods. High machine rigidity suppresses vibration and enabling stable EDM. Micro hole processing is also possible.

X:300 Y:250 Z:200

Micro-hole: 0.15 mm

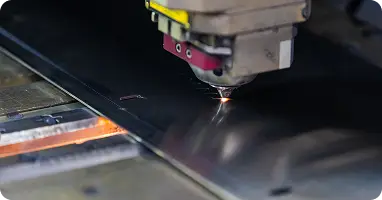

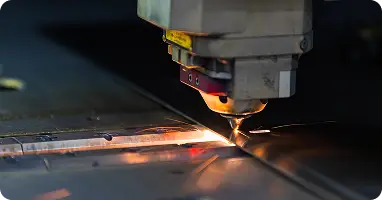

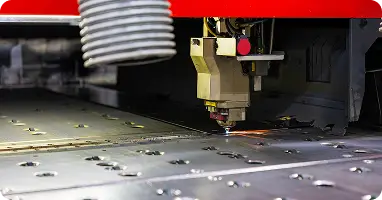

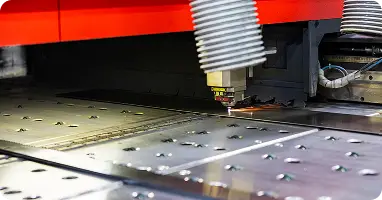

Laser machine achieving high-speed, high-quality processing

SK material 0.1 - 10mm

SKH 0.8 - 6.0mm

SUS 0.5 - 6.0mm

T=10、1200×2400

measuring machine

Designed for highly precise dimensional measurement, particularly in areas where traditional tools like calipers or microscopes fall short. Measurement by probe (spherical). A stationary measuring machine obtains three-dimensional coordinates from length, width, and height, and measures the dimensions, positional relationship, contour shape, geometric tolerances, etc. of an object with high precision.

Three-dimensional measurement inspection. Measurement inspection of all products (except micro products). in addition to basic measurements, roundness, concentricity, parallelism, and straightness are also measurable

X:500mm、Y:700mm、Z:400mm

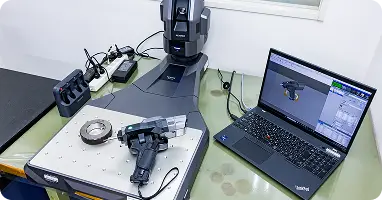

±0.1μm high accuracy measurement is available. A combination of touch probes, multi-color laser systems, and high-definition image measurement offers a powerful approach for accurate 3D measurement of workpieces with complex shapes.

Three-dimensional measurement inspection. Measurement inspection of all products (mainly micro products). in addition to basic measurements, roundness, concentricity, parallelism, and straightness are also measurable

Wide-field measurement 325 mm x 175 mm

High-precision measurement 306 mm x 156 mm

The system is portable with handheld probe, so large workpieces and installed workpieces can be measured on-site. Just placing the probe achieves high-precision measurements of up to 0.01 mm.

Items that are difficult to measure with the above two machines, items that require high-precision measurement, cylindrical items

X:2000mm、Y:1200mm、Z:1000mm

Adopts an electromagnetic force (force motor) load mechanism. Freely select different test forces with high precision. Four types of system are available for different purposes; a large number of tests can be efficiently conducted.

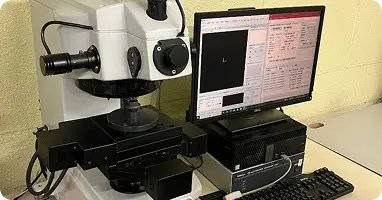

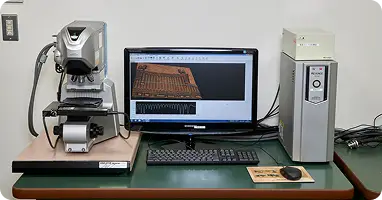

High-definition images clearly capture even minute scratches, defects, and complex three-dimensional shapes. Unique functions such as autofocus and automatic image merging enable efficient observation and measurement. In addition, we have a total of five microscopes with identical performance at our sites, enabling real-time inspections to the same standards.

High resolution image: 4000 (H) x 3000 (V) pixels

High-definition mode: up to 12000 (H) x 9000 (V)

A high-performance non-contact high precision 3D surface profiler capable of measuring nanometer, micrometer, and millimeter microstructure. Captures the surface roughness and shape of any material in high definition.

Height measurement range: From a few μm to a few mm

Lateral measurement range: From several tens of μm to several mm

Please feel free to request anything from detailed product information to product samples.

For inquiries or questions, please call or submit the contact form below.

Sundays, and holidays