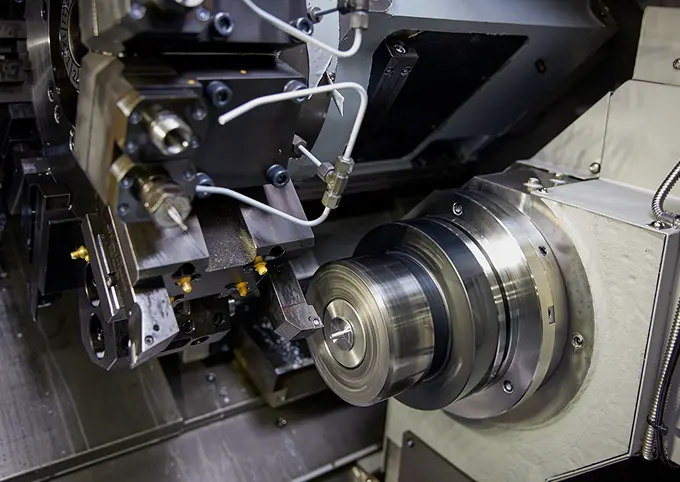

Offset Printing Machine Spare Parts

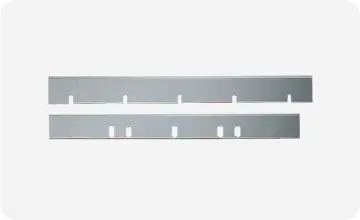

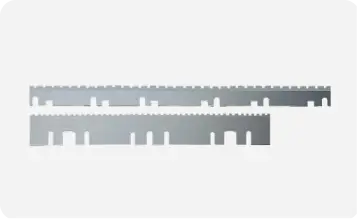

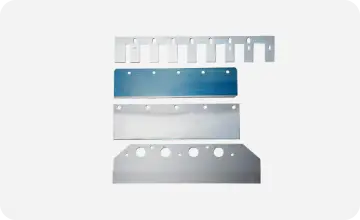

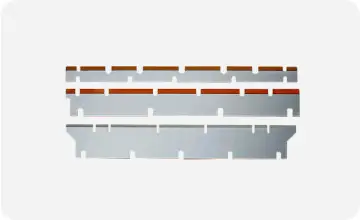

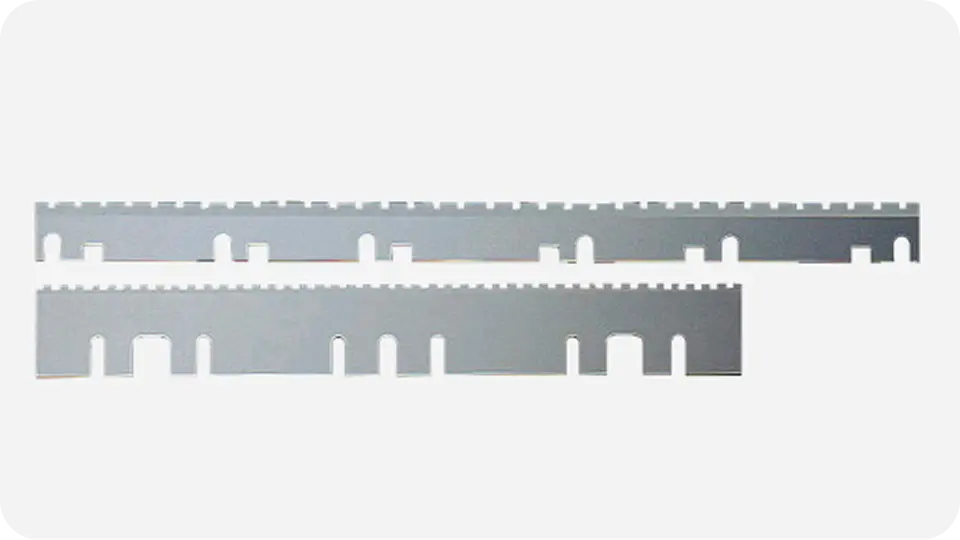

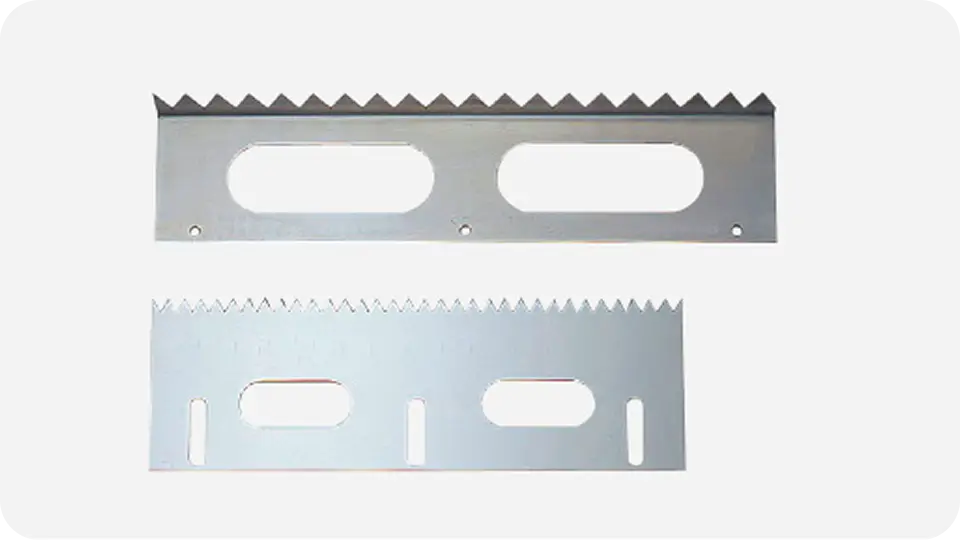

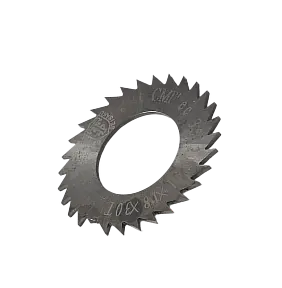

Flat processing products (various cutters and blades)

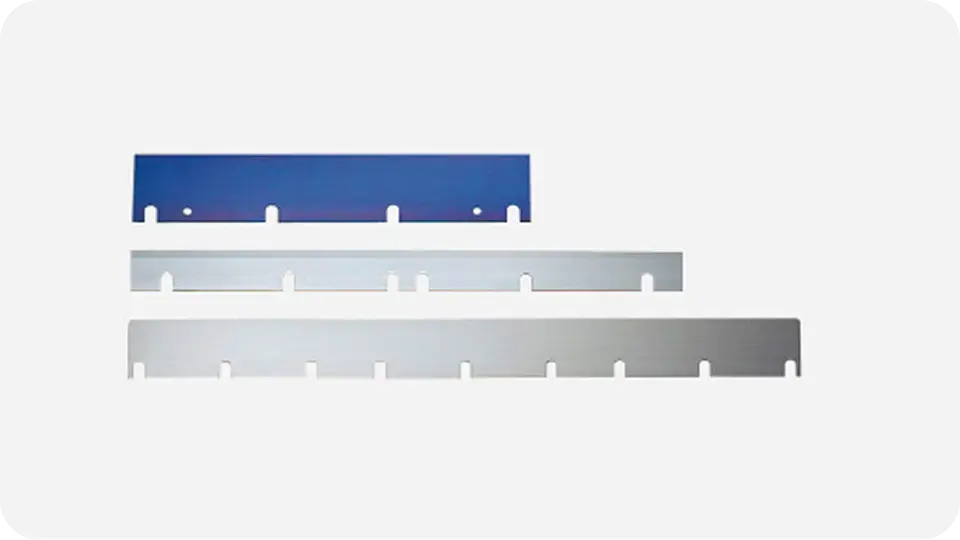

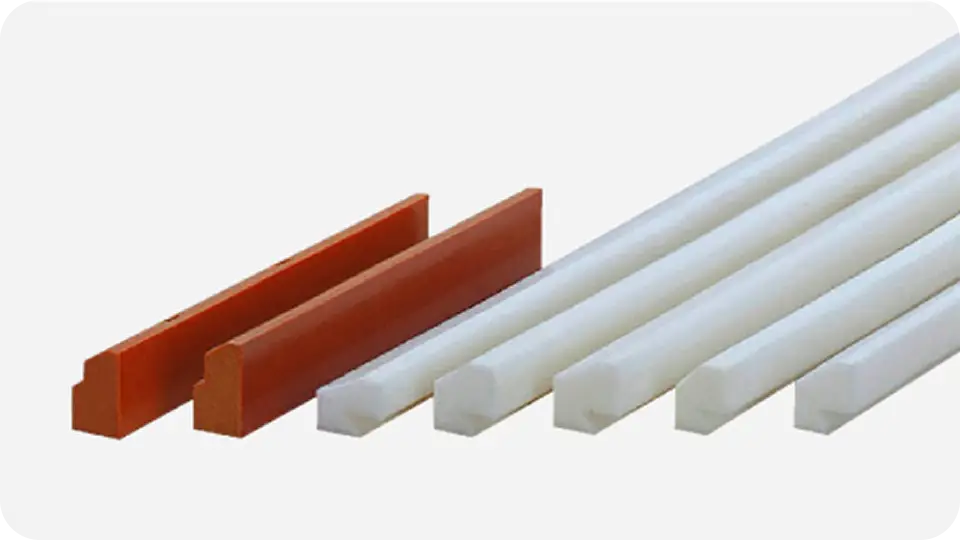

Square processing products

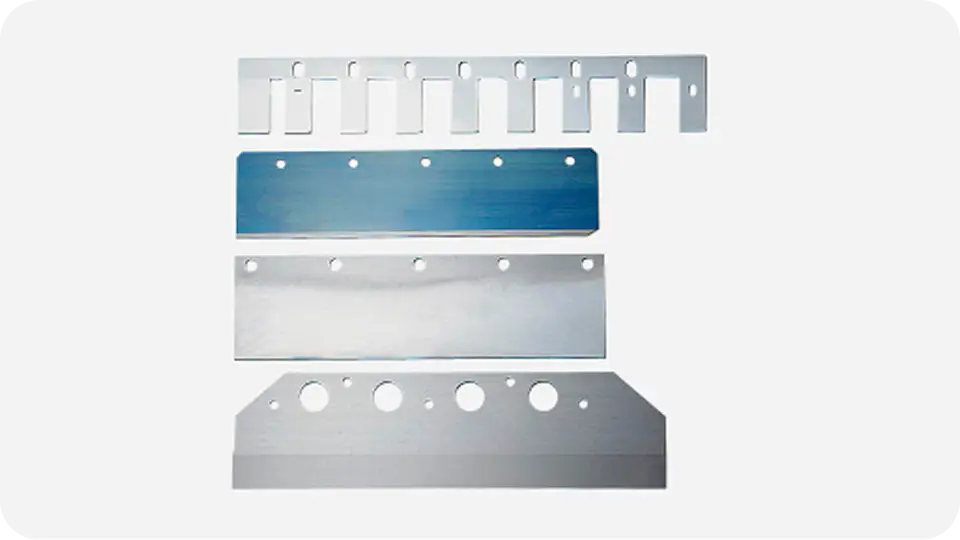

Round shaped processing products

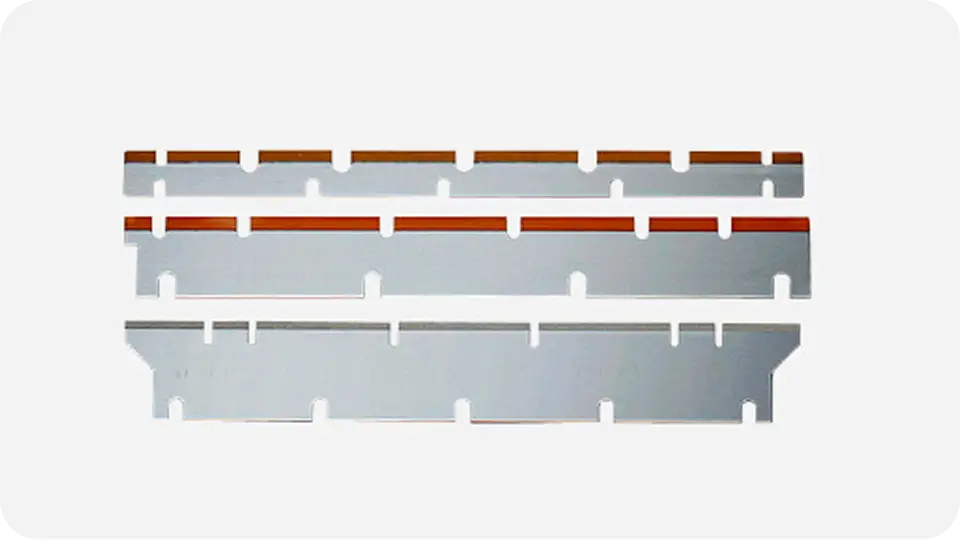

Spring steel processing products and bent processing products

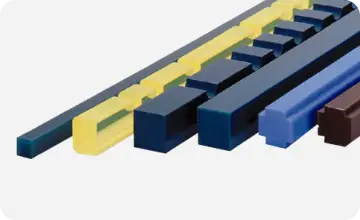

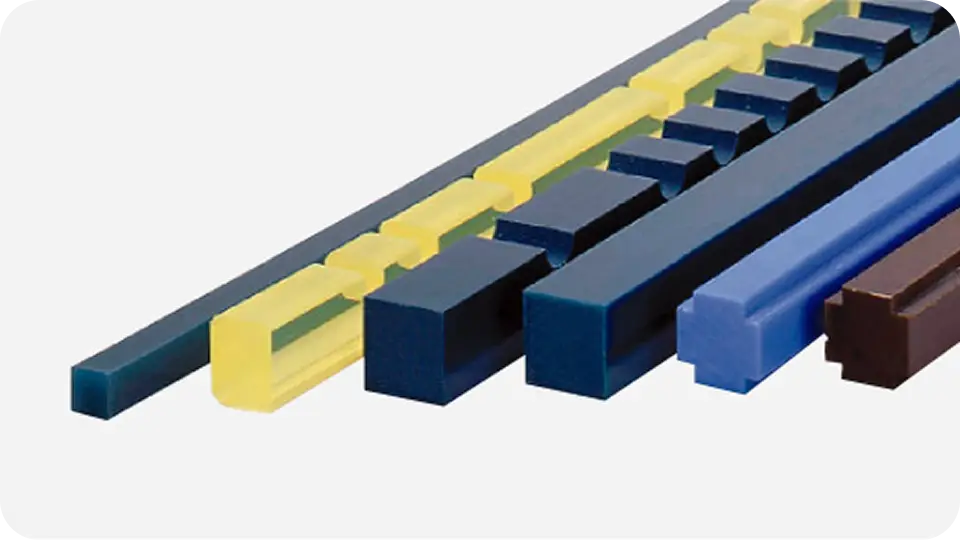

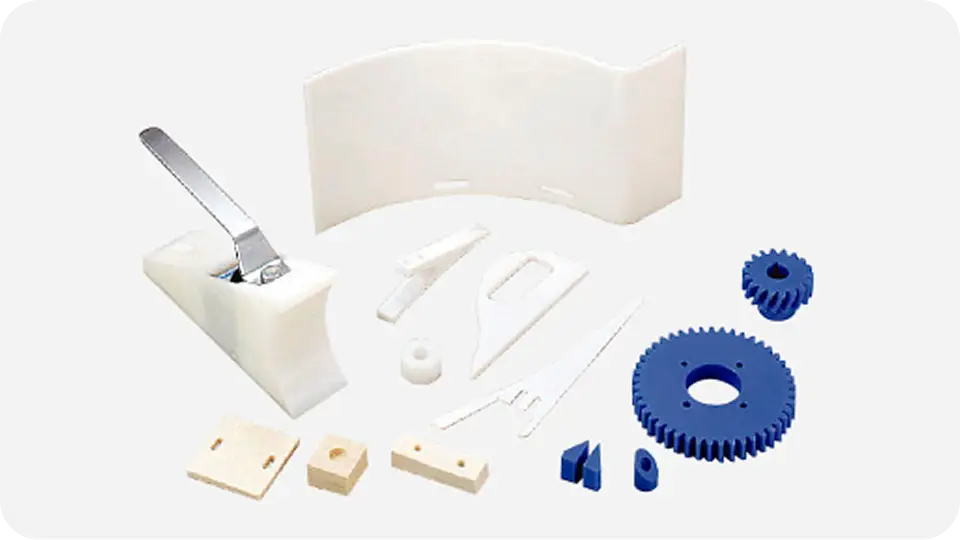

Resin processing products

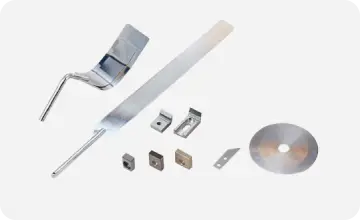

Needle, Key, Gripper

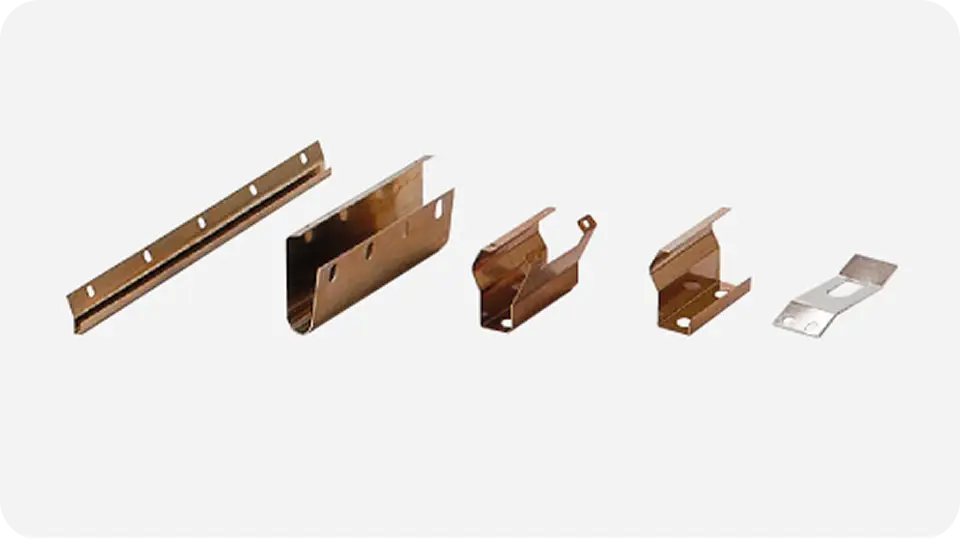

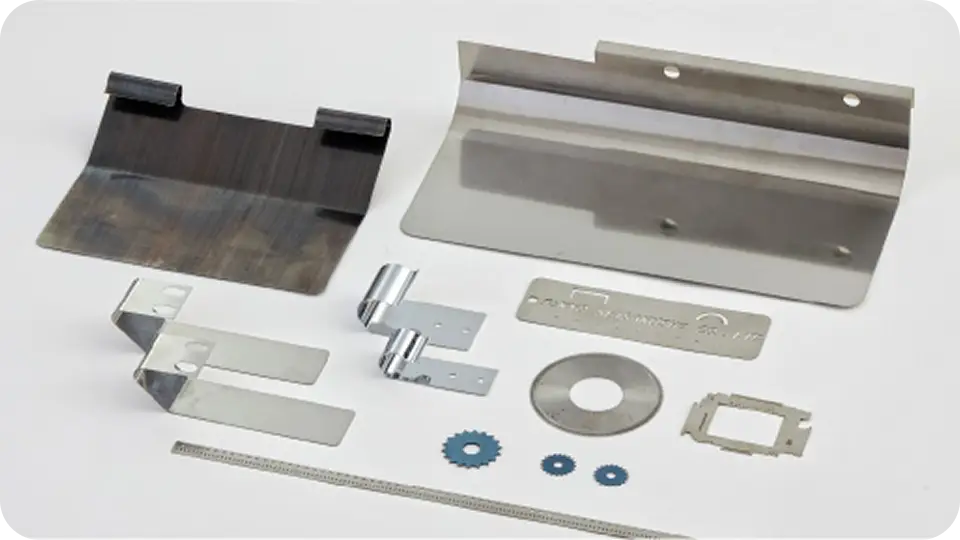

Sheet metal processing products and other processing products

Product Lineup

Flat processing products (various cutters and blades)

Square processing products

Round shaped processing products

Spring steel processing products and bent processing products

Resin processing products

Needle, Key, Gripper

Sheet metal processing products and other processing products

CONTACT

Please feel free to request anything from detailed product information to product samples.

For inquiries or questions, please call or submit the contact form below.

For inquiries or questions, please call or submit the contact form below.

Inquiries by phone

Reception hours: 8:30 AM–5:00 PM, closed on Saturdays, Sundays, and holidays

Inquiries about doctor blades

+81-3-3902-1317

Inquiries about our other products

+81-3-3902-1316

Please feel free to request detailed product information or product samples.

For any inquiries, please contact us by phone or through the contact form below.