After-Sales Service

AFTER SERVICES

At Tokyo Seisakusho, we believe that true quality lies not just in delivering a product, but in the follow-up that comes afterward. We present our framework for supporting your operations, covering everything from resolving issues after delivery to enhancing quality on an ongoing basis.

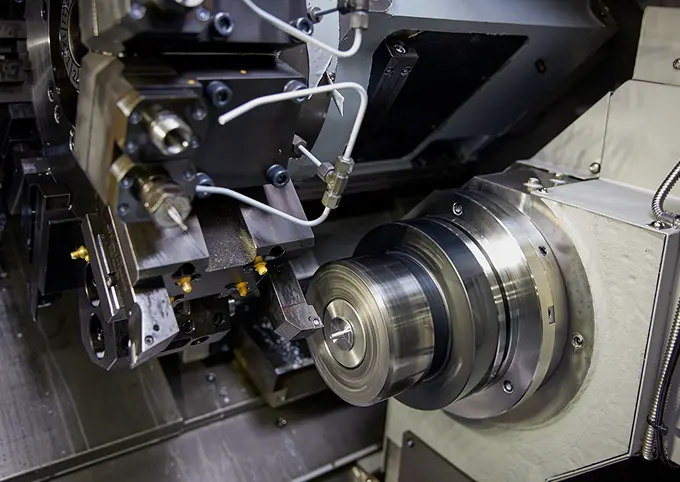

Follow-up structure in place offering peace of mind after delivery

To prevent post-production issues and a loss of quality, Tokyo Seisakusho prioritizes following up with customers after delivery. If issues such as breakage or poor sharpness occur, we offer same-day proposals for replacement or repair. Through precise edge corrections and adjustments, we deliver product value that exceeds expectations.

Extensive quality checks using the latest inspection equipment

Our quality management incorporates the latest inspection equipment, including KEYENCE microscopes and laser-based microscopes. We precisely measure tolerances, surface roughness, and cross-sectional shapes and also develop specialized fixtures internally when required. We enforce strict process management at each production stage to guarantee that every product conforms to required standards.

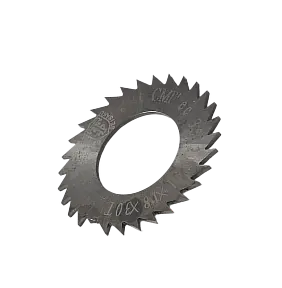

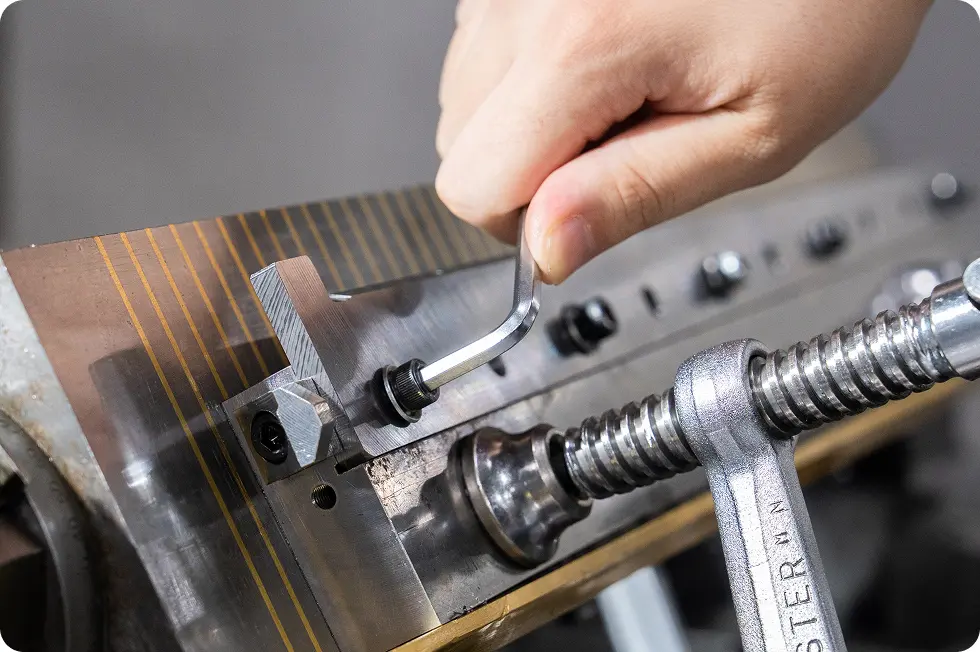

Implementation of the latest inspection equipment

Microscope

These measurement devices record “cross-sectional profile measurements,” key to doctor blade development and production processes, allowing for cross-product comparisons. As a blade manufacturer specializing in micro unit-level precision components, we are committed to implementing tools and processes that further improve accuracy. In the event of an issue, we leverage customer insights and the extensive experience of Tokyo Seisakusho specialists to identify likely causes, examining factors such as the cause of the problem, blade wear patterns, and signs of surface damage. Following this, thorough verification and analysis is performed under a microscope.

Shape measurement laser microscope

We measure factors that are difficult to assess from cross-sectional shape alone, including surface indentations, the presence of microscopic foreign substances, and precise values for surface roughness.

A same-day response to defects and other issues can be offered.

In situations requiring urgent action, such as unexpected machine shutdowns, we reduce disruptions through prompt solutions, including replacement shipments from inventory or same-day repair services. In particular, we specialize in straightening bends and correcting distortions at the blade tip, achieving both rapid same-day delivery and uncompromising quality.

Ongoing pursuit of quality

After delivery, we visit our customers’ work sites to conduct hearings on how our products are being used. We incorporate customer improvement requests, with improvements reflected in the design drawings and specifications of future products. Rather than simply completing production, we aim for “durable quality,” continually improving and offering new solutions.

Please feel free to request detailed product information or product samples.

For any inquiries, please contact us by phone or through the contact form below.